Quality

DETAILS THAT

Certifications

Certifications in the world of mechanical processing are an element that represents the essential standard to enter the market. Officina Meccanica Roselli has been ISO certified since 1994, and today is also ISO 9001: 2015 and IATF 16949: 2016 certified. This quality process guarantees constant control of production. Officina Meccanica Roselli is constantly committed to research and technological development, a behaviour that can be seen in the large investments made, in the technologically advanced machinery, but also in the support processes for mechanical processing.

Tests and measurements

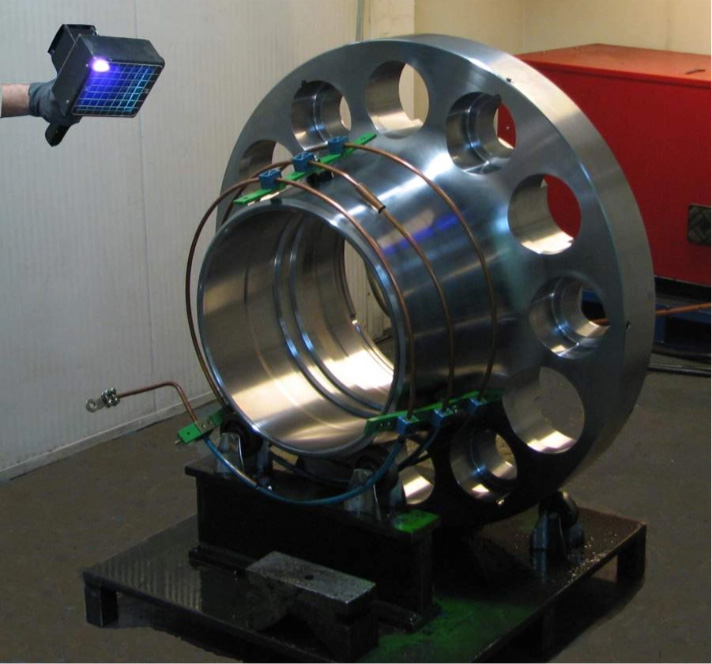

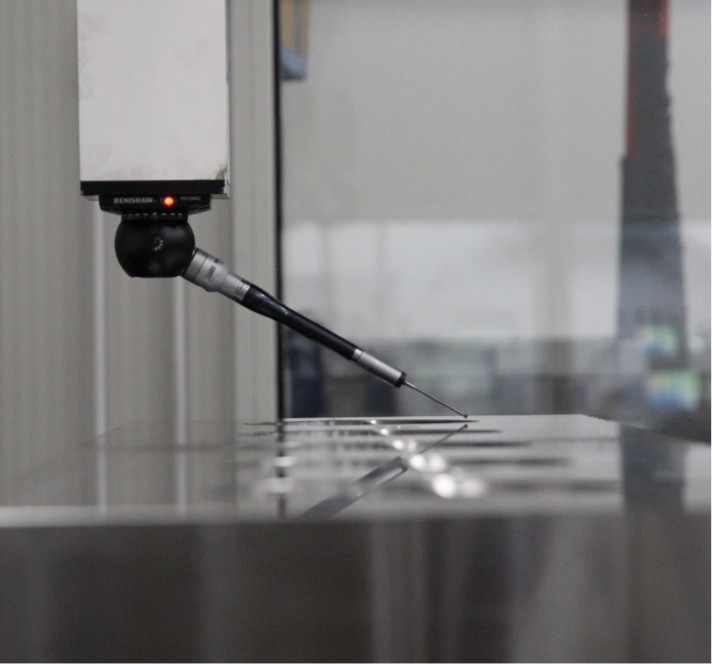

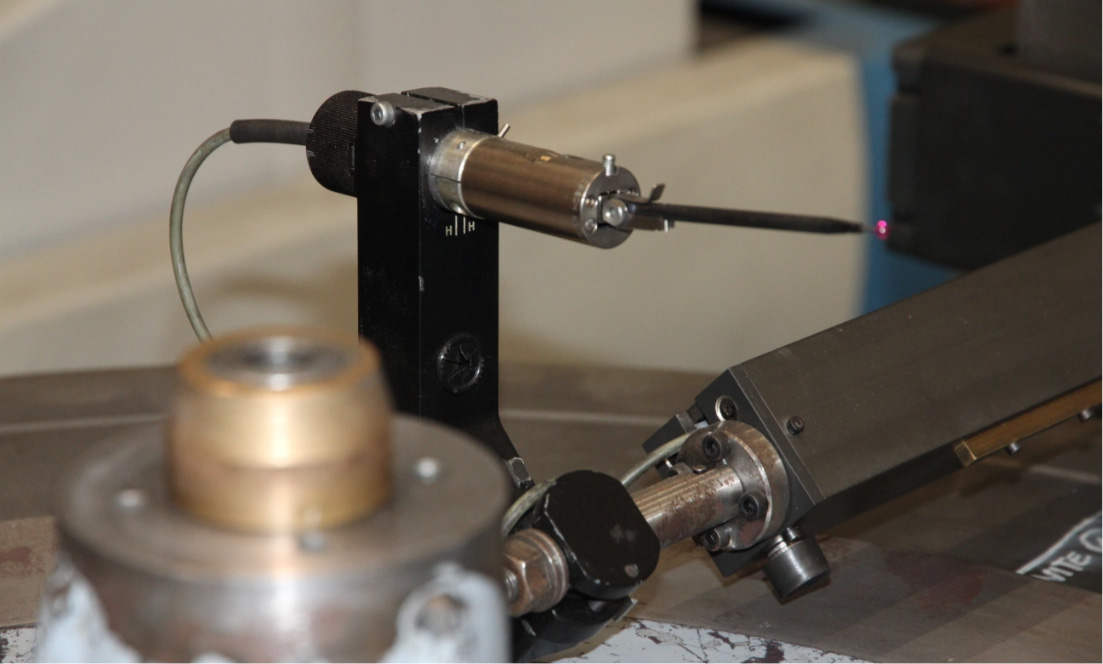

Quality control is an added value that brings the precision of Officina Meccanica Roselli’s products to very high levels. The company is equipped with an air-conditioned and temperature-controlled measurement room. Inside it are tools and equipment necessary for testing and precision dimensional control such as ultrasounds, magnetic controls, penetrating liquids and pressure tests. The company carries out stringent measurement and quality control tests on its production with:

Product quality is also guaranteed thanks to off-line programming and simulation, which reduces production start-up times and errors in the processing phase.