Technology

IN STEP WITH THE TIMES

Experience, professionalism, latest generation technology and dynamism represent the winning combination that today allows Officina Meccanica Roselli to manage the main precision mechanical processes in many sectors and especially on large components.

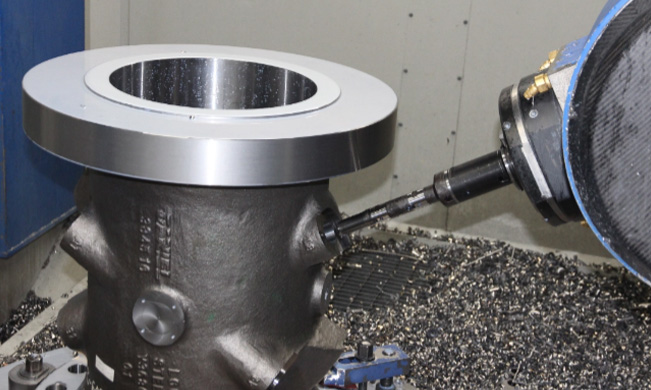

Customised milling, turning, boring and accessory machining are carried out in the new plant.

The machining centres can process components up to dimensions of just over 3 metres, with a range from 3 to 5 machining axes, all multi-palletised to optimise production changes. Many machines are equipped with a horizontal and vertical head and 4 machines have a tilting head for maximum flexibility.

All types of metals are processed, with special attention given to especially challenging ones, thanks to particularly powerful and extremely rigid machinery.

Main processes

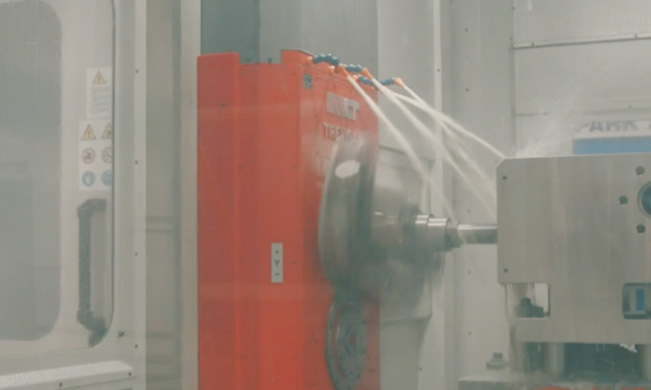

Vertical turning

Turning is a chip removal carried out through the rotation of the piece to be machined while the cutting tool remains stationary. Vertical turning, in particular, rotates the piece on a vertical axis and is mainly suitable for pieces with a diameter that is proportionally larger than the length. Officina Meccanica Roselli can turn pieces up to 3.6 metres, up to a height of 2 metres.

Officina Meccanica Roselli uses

Trevisan, Mandelli, Toshulin and Pama machining centres.