Sectors

ALWAYS PRESENT WHERE

Oil & Gas

Oil & Gas

In this sector, the transformation of liquid and gaseous natural resources into energy from combined cycle power plants fuelled by natural gas requires components constructed with the highest resistance and greatest precision. The oil and gas market is a very demanding market. To meet the needs of its customers, Officina Meccanica Roselli has developed know-how and excellence in its production procedures, to process components for oil plants, oil refineries, offshore platforms, extraction plants, storage and natural gas pumping facilities. The main manufactured components are:

• Valves

• Riser Flanges

• Components for Blowout preventers (BOPs)

• Compressors

• Clamps

• Fluid Ends

• Conductor Housings

• Wing Blocks

• Flow meters

• Pistons

Automotive

Automotive

Since its inception, Officina Meccanica Roselli has always supplied a wide range of products to companies in the automotive sector, manufacturing numerous components that require a high level of precision and a particular degree of tightness. These products are intended for the industrial, agricultural and military vehicle sectors and recently for industrial vehicles with electric traction. The company’s high-tech machine fleet makes it possible to create:

• Oil pans

• Gear Boxes

• Bridge Boxes

Nuclear

Nuclear

In search of sustainable energy solutions, Roselli has successfully begun working in the Nuclear sector, in particular for the ITER cold fusion project, creating parts with extremely precise and complex shapes that, when assembled, will form the TOKAMAK, the pulsating heart of the cold fusion reactor. In order to be able to create products aimed at this application, the processing, handling, control and preservation standards of components have been further raised, with areas dedicated to anti-contamination.

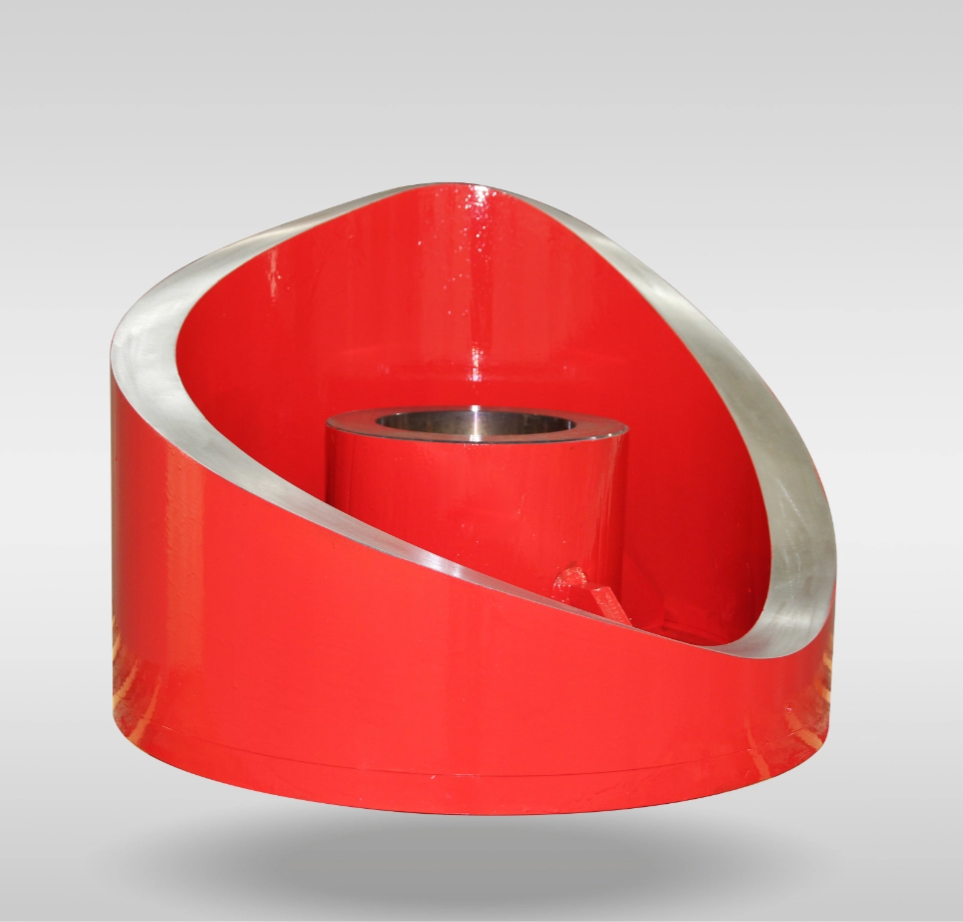

Drawing cams

Drawing cams

One of the sectors where the company can now be considered a leader is in the production of drawing cams. Combined cold drawing lines are mainly used to produce bars or tubes by cold forming. Depending on the material to be processed (steel, brass, copper, aluminium, etc.), the systems are composed of different elements. Drawing forces can fluctuate between 2 and 46 tons and the cams that support the production require considerable solidity and precision. recent years, the company has introduced a major change in the production of drawing cams, replacing castings with forgings, to ensure better quality and a total absence of defects. The company supplies spare parts for Kieserling, Schumag, Danieli and OCN machines and can also provide technical support in co-design activities for new models or customisations. Thanks to the new forging technology, Officina Meccanica Roselli is able to supply any type of cam without the need for models.