Design

WE DESIGN AND

Officina Meccanica Roselli supports its customers in the development and customisation of their needs: from the analysis and optimisation of the projects supplied to the study and definition of original technical drawings. The internal design studio is made up of a team of engineers with extensive experience in various application sectors. Following strict control phases, they can guarantee efficient production programmes.

The design studio carries out simulations with CAD software, which allows them to test every detail of the machining process.

This is an efficient way to manage internal resources and specialised technicians, which thus allows us to reduce programming times while guaranteeing a high level of quality. With this simulation method, the project is applied virtually, checking the machine positions, the production times and the precision of the final result, thus optimising the entire production process and ensuring maximum precision.

Officina Meccanica Roselli supports customers in the development of new products and in particular in the production of castings, with co-design activities, prototypes and series optimisations.

Latest achievements

ITER project

Officina Meccanica Roselli, increasingly engaged in the nuclear sector, is now the supplier of the ITER project, the world’s largest nuclear fusion plant company and which could significantly contribute to meeting the clean energy needs of the future. The ITER project was signed by 7 partners in 2006: China, Euratom, India, Japan, South Korea, Russia and the United States. The headquarters of the first plant is in Cadarache (FR), on a 42-hectare site. ITER is one of the most complex engineering projects in history, as it will require millions of components to assemble the giant reactor which will weigh 23,000 tons.

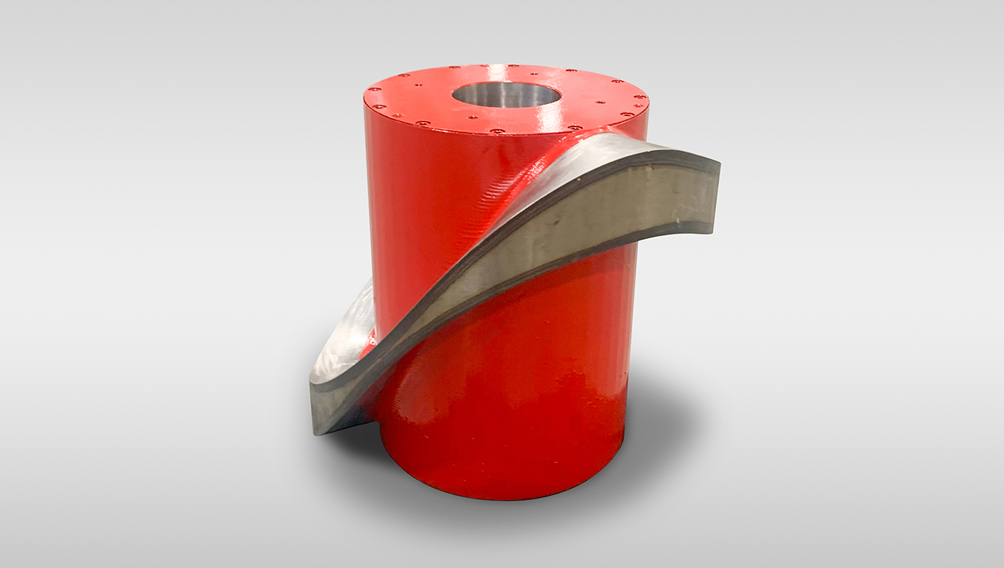

Cams for combined drawing machines

Officina Meccanica Roselli, backed by extensive experience in this sector, has introduced a great innovation in the production of “drawing cams”, replacing castings with forgings, to ensure better quality and a total absence of defects. The company can supply spare cams for Kieserling, Schumag, Danieli and OCN machines and can also offer technical support in co-design activities for new models or customisations. Thanks to the new forging technology, Officina Meccanica Roselli is able to supply any type of cam without the need for models.